When I put the first Slash MT together, I used my LCG all blue Slash and it worked great but the blue was a limiting factor when it came to body color schemes. I wanted to do things a little differently this time around and keep the chassis all black to open up my options when it comes time to switch up the look with a fresh body. This truck is fairly simple with only a few mods separating it from stock. I wanted a considerably wider track while still being able to source replacement parts should I break an arm in the field. I didn’t want to go with a one-off piece that would need to be ordered and that’s where the stock Jato parts come in handy.

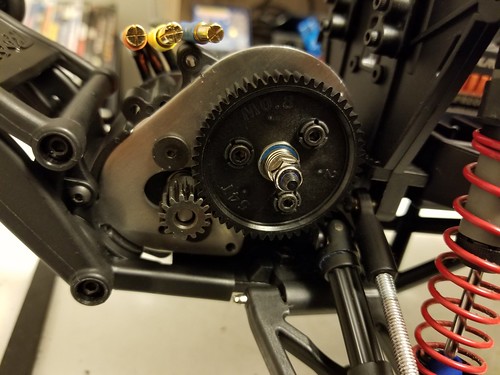

I started out with a HCG roller that came without most of the parts that were going to be replaced anyway. The first change was to switch the stock trans case out for a RPM Hybrid gearbox. This made it easier to mount the Jato arms since I would have two chances to get the trimming of the toe blocks right. I needed to trim these down slightly as the spacing on the Jato arms is a little smaller than the stock Slash arms or the slightly wider Rustler/Stampede units.

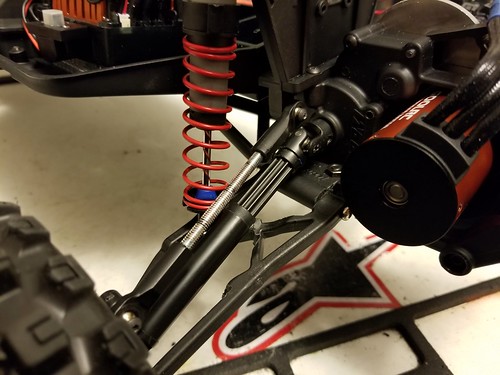

These photos were taken with a second set of front arms that were later replaced with the correct rears. The fronts don’t allow clearance for the driveshafts and the shocks are held at an odd angle. The rear arms solve both of these issues. The Jato arms also need a considerable amount of trimming in the webbing to allow for driveshaft clearance. If I had to do it over again I would use an alloy arm to retain some more structural integrity in this area. I usually don’t like using alloy arms as they tend to cause other, more difficult to replace, parts to break. Its easier to replace an arm than a transmission case.

Next up was changing out the stock Slash driveshafts for Jato units. The Slash shafts are a little short for the length of the arms and admittedly, the Jato’s are too. They are at their limits when paired with the Magnum 272 tranny with its narrow diff. I run them on a few other projects and they are holding up fine but should they give up the ghost I’ll switch them out for something stronger. The Jato shafts are paired with Slash 4×4 heavy duty output yokes and stub axles. These solve the issue of the larger u-joint balls, which would require drilling the stock parts to the point of compromising their strength, as the Jato shafts and Slash parts are 100% compatible.

The front arms are a little more involved. The bulkhead needs to be trimmed slighly to allow the arms to fit without compromising the strength of the arms. The outer hinge pins need to be changed to the same units as the rear outer pins and the caster blocks need to be drilled to fit the larger pins. The arms needs to be clearanced to allow the caster blocks room to move without binding.

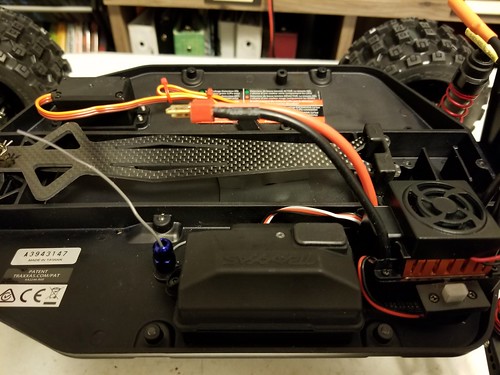

For electronics I am using a PowerHD 1501 MG servo with an alloy horn, a Radiolink R4EH-G receiver, a GoolRC 60a waterproof ESC, and a 3660 4-pole 3800kv motor. I swapped in a 32p 54t spur from the Jato and paired that with a 17t 5mm bore pinion.

For the finishing touches I mounted the Pro-line Chevy Silverado body with a complete set of RPM adjustable body mounts. The 12mm hexes were shelved in favor of Hot Racing’s splined 17mm hexes and the Pro-line Badlands MX28’s were slid in place. I chose the widest offset available for the wheels which is PL’s part number 10125-18. Finally I took a page out of Arrma’s playbook and lined the sides of body with thick decals on the inside to prevent the chassis tub from rubbing through the paint. It works well on the Senton MEGA so I replicated it here.

Seeing as I live in West Virginia and it is February the weather is not conducive to running outdoors. I haven’t had a chance to run the truck yet and that is also why all of the shots were taken at my temporary bench in my office. As of this morning we still have 3 inches of ice in the driveway and 8 inches of snow in the yard. As soon as the weather breaks I am going to get the truck out in the dirt and give it a proper shakedown.