As we all know, RPM makes some of the most durable upgrades on the market and you can nearly build an entire Slash using just their parts. My naja bug long travel Slash has quite a few of their parts including rear arms all the way around, the transmission case with the aluminum motor plate and optional toe blocks, front and rear skid plates and now the new front bulkhead, all in blue. I have never broken a front bulkhead on this truck but have sheared the mounts off where the shock tower mounts in very cold weather on my Rustler so i thought that i would give the new bulkhead a try. The bulkhead is made from RPM’s famous blend of nylon and carries their limited lifetime warranty. The bulkhead is advertised as 15% lighter than a stock bulkhead and comes with a removable dust plate for use in applications where the front bulk is left open (such as the Rustler, Bandit and Stampede) but is not used on the Slash due to its front bumper covering the entire bottom of the bulk. The area that the dust cover encloses can be filled with weight to adjust the weight bias of the truck as well.

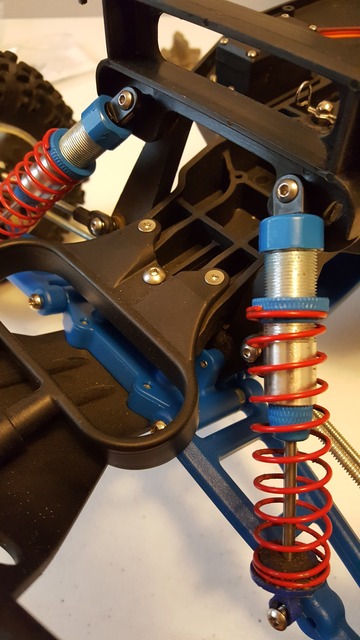

Initially, i am pleased with the fit and finish of the bulkhead. The screws hold tighter than in the stock unit and hopefully that will help prevent any screws from loosening over time. The screws have more resistance going in but aren’t so tight that you risk stripping a screw. The bulkhead feels as stiff as the stock piece once installed. As soon as the snow melts i’ll get the truck back out to the skate park and give the new parts a thorough workout. So far i am happy with the new bulk and i feel like it a great deal at less than $10. Here’s how it looks installed:

UPDATE: I got the chance to do some testing with the RPM bulkhead and front arms today. This was nerve-racking to say the least! I have some steel re-bar that marks the edge of my property (the property next to mine is being sold and i requested the area be surveyed so that i don’t get my property sold too) and thought that would target the damage to a smaller point. The rebar is driven into the ground to about 36″ and there is another 36″ above ground and is 3/4″ (or #6) in diameter. The truck now has a 4300kv 4pole on 2s and is geared 18/86 so it is geared more for torque than top speed but it is still plenty fast to break some parts. I targeted the impact at the mid-point of the arm to test the arms as well as the bulkhead. When impacting the arm at its mid-point the truck would spin quickly to the side of the impact but at no point did i hear any snapping sounds or see any damage. I repeated this test a total of 15 times on each arm and other than superficial scratches the arms survived the torture. I am very impressed with how resilient the arms are compared to stock. I then moved the point of impact to the wheel which put more leverage on the arm and therefore the bulkhead. The sound was sickening; the only way i can describe it is “KA-THWACK”. The truck not only pirouetted up and to the left (it was a hit to the left side) but also end over end. The damage? The caster block broke (it was stock), and the king pin bent at a 45 degree angle. The bulkhead is fine, the arm is fine, even the steering and toe links are fine. I was genuinely surprised that nothing broke, not because i doubted that the RPM parts would survive, but because the hits were that gut wrenchingly hard. I am very pleased with how well the parts took the abuse.

On a side note, i did not notice any loss of front traction due to the lighter weight of the bulkhead on the mixed surfaces that i drove on today, but that doesn’t mean that i won’t need to add some weight to the nose once i take the truck to the track (or move the bulkhead to my LCG track prepped truck). The bulkhead survived all of the punishment that i threw at it and still looks as good as it did out of the poly bag, so i can say without question that i recommend this part to anyone with a Traxxas 2wd. It is inexpensive, as durable as a claw hammer, and adds another point of tuning ability to a platform that can benefit from more options and that is a very good thing.

UPDATE #2

I took the RPM arms and bulkhead back off today and re-installed the stock parts to see how much of a difference the RPM parts make. I also put another set of stock caster blocks and knuckles on the truck just to get it back up and running. I only had a little time before the rain set in for the day so i didn’t get to do as much of an extensive test as i did with the RPM parts but it turns out that i didn’t need it. On the first hit the truck spun just like it did before and drove away cleanly but on the second pass it all went south. I hit the re-bar with the left front tire and the truck went left and up and when it came down it wasn’t going anywhere. The caster block was sheared again, the king pin was bent, the hinge pin holes in the arm were split, the lower shock screw was missing and the hinge pin mounts on the bulkhead sheared off and stayed with the arm. Two crashes was all that it took to completely destroy a stock bulkhead and arm while the RPM parts survived more than 30 impacts with no damage (the only parts that failed were stock parts during that first test). If that doesn’t speak to the durability of the RPM plastics, nothing will. Disclaimer: I paid for these parts out of pocket, these were not provided by RPM nor was i paid for my review of these parts. I didn’t get any video or photos of the tests unfortunately; it was threatening to rain and i was by myself so i didn’t set up any camera equipment. I will be replacing the bulkheads on all of my Traxxas 2wd’s as they break with RPM bulks which the way i have been driving lately may not take long at all!

UPDATE #3

I took the truck out this evening and ran it just for fun. I got to run a few packs before the sun went down and things got cold. I lost sight of the truck momentarily and clipped a telephone pole. The impact was pretty loud but thankfully didn’t do any damage. The area that I was running at had some construction barriers around the edge that I was focusing on not hitting and then I had a brain fart and “thud”, it hit dead center of the bulkhead. I hadn’t re-installed the front bumper from my last test so the truck hit the pole bulkhead first and I thought for sure that the bulk had cracked. The truck came to an abrupt stop from about 2/3 throttle and then came back down in its own tracks. I am pleased to say that the bulkhead survived without any cracks or damage other than superficial scratches. I am hoping to do some testing on a track soon to test the weight difference between the RPM bulk and a stock Traxxas piece and see how adding weight affects the truck. I haven’t noticed any ill effects of the lighter RPM piece as of yet even on pavement but I am curious to see how adding a little weight changes the front grip.

Link: http://www.rpmrcproducts.com/shop/ch…-110-scale-2wd